Aluminum vs. Copper Crush Washer: Choosing the Right Seal for Your Application

What makes crush washer important in a water system, be it automotive, plumbing, or hydraulic machinery? These small yet critical components play a pivotal role in establishing and maintaining a dependable seal within pressurized systems. Among the array of materials designated for crush washer, aluminum, and copper emerge as preeminent contenders due to their distinct properties.

Aluminum crush washer offer distinct advantages, such as light weight and corrosion resistance, making them suitable for applications where low weight is required or where corrosion is a concern but unlike copper washers, they are not stable pressure or overheating edge.

Photo: Use of Aluminum Crush Washer

On the other hand, copper crush washer excel in their malleability and conformability to irregular surfaces, ensuring a tight seal They exhibit good thermal conductivity and flexibility under high pressure, making them ideal for harsh environments.

Photo: Use of Copper Crush Washer

It’s important to understand the difference among aluminum & copper crush washer and choose the most appropriate option for a specific application. Factors such as operating conditions, pressure levels, temperature variations, and recycling requirements must be considered to ensure proper seal performance in fluid systems.

The Role of Crush Washer

Before you get into aluminum vs. copper crush washer debate, it is important to understand their basic function. Synonymous with sealing washers Crush washer act as sudo, thin gaskets commonly used around fittings, plugs, bolts or parts to hold a tight seal These washers deform under pressure, thus absorbing gaps between the two elements effectively. This twist ensures a tight seal that reduces the chance of leaks in systems that control water or air under pressure.

Their importance lies in their ability to cope with irregularities in longitudinal regions, and to compensate for possible errors. This feature enables crush washer to seal joints effectively, which is important in applications such as automotive engines, hydraulic systems, plumbing installations, etc. The choice of aluminum or copper crush washer often includes material hardness, compatibility with specific fluids, Thermal conductivity is also a consideration, which affects the efficiency and durability of seals under operating conditions an understanding of their primary purpose helps to make informed decisions about their selection based on the needs of the intended application.

Aluminum Crush Washer

Aluminum crush washer is highly valued for their unique lightweight characteristics, making them the best choice in a variety of materials, especially where weight plays a key role Their inherent advantage lies in the ductility of the material of the phenomenon, allowing effortless deformation under pressure. This quality allows the washer to expertly adapt to the intricacies of the mating parts, facilitating a better fit and reliable sealing.

Photo: Aluminum Crush Washer

The flexibility of aluminum crush washer is particularly useful in situations where seal accuracy is critical for optimal performance Whether in automotive engines, plumbing systems, aerospace equipment, the power of these washers the consistent and secure seal not only provides reliability but can provide reduced leak performance -Contributes significantly to overall operational efficiency by increasing safety and security.

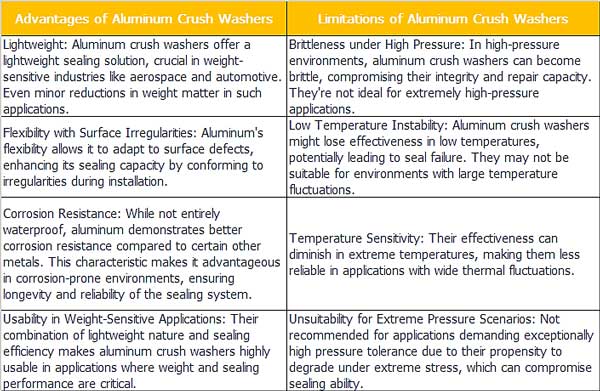

Table: Advantages and Limitations of Aluminum Crush Washer

The unique characteristics of aluminum crush washer provide significant advantages in certain applications, especially where weight, adaptability to surface irregularities, and corrosion resistance are crucial. However, their limitations, particularly in high-pressure environments and temperature sensitivity, restrict their suitability for extreme conditions, necessitating the consideration of alternative materials in such scenarios.

Copper Crush Washer

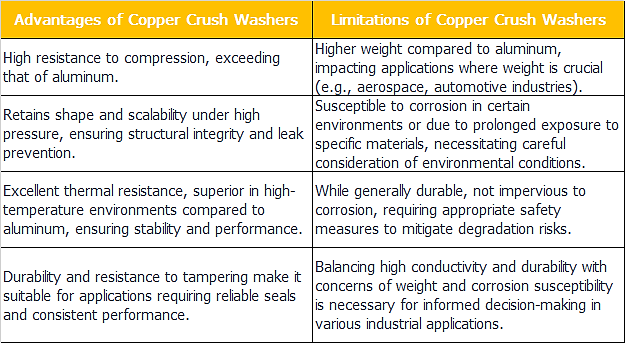

Here’s a tabular representation outlining the advantages and limitations of Copper Crush Washer:

Photo: Copper Crush Washer

Table: Advantages and Limitations of Copper Crush Washer

This table summarizes the key advantages and limitations, using Copper Crush Washer, highlighting its strengths in high compression resistance, thermal stability, durability, and reliability, while acknowledging challenges related to weight, corrosion susceptibility, and the need for careful consideration of environmental conditions.

Choosing the Right Crush Washer

Choosing aluminum or copper crush washer requires careful consideration of several factors, which are primarily influenced by the specific requirements of the application A key determinant is the required pressure. Copper washers excel in high-pressure situations because of their inherent durability and durability. Copper’s high flexibility permit it to withstand extreme stresses better than aluminum.

However, in situations where weight plays an important role, such as aerospace applications, the lightweight aluminum component may take precedence over other considerations Despite its lower tensile strength compared to copper about, the benefits of weight savings can be significant in some industries where every ounce counts.

Another important consideration is the environment in which the system operates. It is important to examine the potential effects of decomposition. Understanding the corrosion resistance of aluminum and copper helps in making informed decisions. Compared to aluminum, copper generally exhibits better corrosion resistance, making it more suitable for corrosion-prone areas.

The extreme temperatures further cause differences in the performance of these materials. Copper performs well in high-temperature environments, and exhibits greater corrosion resistance compared to aluminum. Applications used in extreme temperatures may therefore benefit from the choice of lead washers.

Finally, the selection process requires micro-analysis of these factors. The trade-off between strength, weight, corrosion resistance and heat tolerance determine the most appropriate choice of aluminum and copper washers, making them ideal.

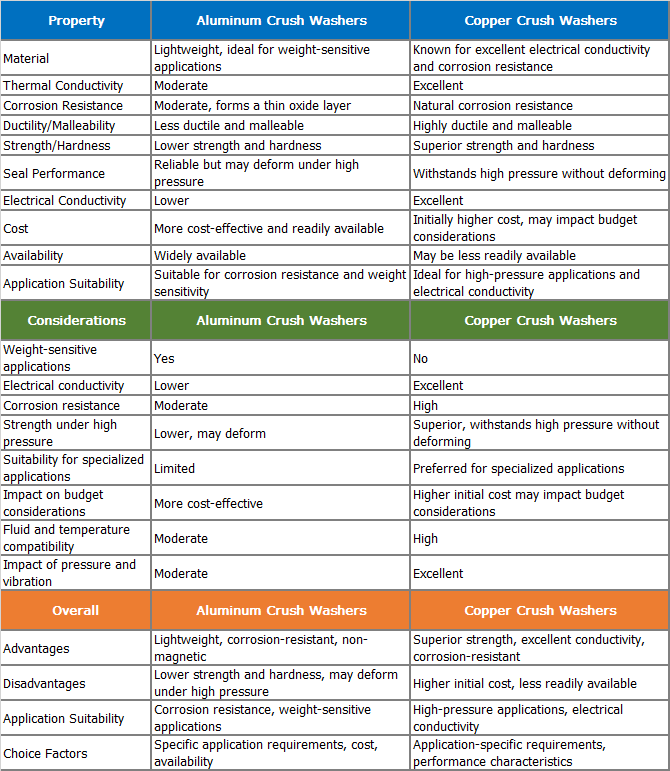

Table: Differences between Aluminum and Copper Crush Washer

The differences provided is a general comparison and that specific use cases may require more detailed analysis to determine the most suitable material for a particular application.

Material Considerations for Optimal Sealing Performance

Aluminum and copper crush washer each offer unique advantages and limitations, so that the choice (aluminum vs copper crush washer) between them depends on the specific requirements of the application so greatly for lightweight materials and ductility, aluminum excels at conforming to irregular surfaces, make sure it fits snug. However, it has the disadvantage of being able to withstand lower pressures compared to copper.

Copper, on the other hand, stands out for its inherent strength, ability to handle stress well, and resilience, which makes it stand out for its environmental resilience around the edge of severe wrapping and maintains seal integrity, ideal for applications requiring durability and high pressure.

Selection is based on a thorough understanding of the application requirements. While the flexibility of aluminum is suitable for some situations, the strength and flexibility of copper exceeds in others, ensuring a reliable seal which is essential for the fluid system Detergents of choice properly contributes greatly to efficient and safe operation, improving efficiency and reducing the risk of slippage or failure.

Copper washers are durable, long-lasting, and ideal for high-temperature and electrical applications. On the other hand, aluminum washers are lightweight and corrosion-resistant, making them ideal for outdoor and low-temperature applications.

Finally, better informed decision-making about choices increases the reliability and security of the system.