Are Oil Drain Plugs Reverse Threaded: Unveiling the Truth

Many questions often arise when it comes to maintaining our vehicles, especially for those who like to get their hands a little dirty under the hood One such question that has confused many people is whether the oil filter switch is provided or.

The confusion surrounding this issue has given rise to controversies and anecdotes among automotive enthusiasts and engineers. In this article, we’ll delve into the subject and uncover the truth about oil filters, how they work, and what they mean for your routine maintenance routine

Oil drain plugs, those small but important things at the bottom of your engine’s oil pan, are generally not wired to the back. Contrary to common misconception, most oil drain plugs follow conventional right-hand plugs – turn clockwise to tighten and rotate clockwise and to make it easier This confusion may be due to some cases where materials or external tones are used on particular models.

However, it is always important to consult your vehicle manual or a trusted mechanic before attempting any repair work. Clearing this confusion about oil drain plug threading can help car enthusiasts and DIY mechanics perform oil changes and maintenance with confidence and accuracy, ensuring that their vehicles will last longer and work better.

Understanding Threaded Fasteners: A Brief Overview

Before examining the complexities of oil filter lines, it is important to understand the basic concept of line packing. These important mechanical components incorporate a number of components, including screws, screws, and nuts, that are critical to keeping the parts strong The threads in these fasteners can take one of two directions: right or left hand.

This difference contains the key to the rotational direction required to tighten or loosen the binder. Right wires require clockwise rotation for stiffness and counterclockwise for weakness, while left wires show the opposite the choice of wire direction depends on application requirements, and the significance of this difference is important for a variety of engineering endeavors including the specific oil drain plug.

The Mystery of Reverse Threaded Fasteners

As we dive into the thrill of packaging with wires on the outside, we find ourselves deviating from the customary rules of rotation. Contrary to the traditional idea of clockwise, counterclockwise wrapping, rotating knotted packaging boldly ventures into self-contained territory in contrast, where grace is turned to unconventional paths This interesting phenomenon finds its purpose in the special circumstances of stability.

Finely designed cables to prevent the unintended consequences of vibrations and impacts play an important role in the structural integrity of various controls One key advantage resides in bicycle mechanics: between the pedal and crank arms the main connection. Here, the reversing lines used on a race bike are above average. By routing cables in opposite directions, these pedals boldly sustain dynamics through pedal movement, ensuring stability along the rider’s journey in all cases

Specifically, the enigmatic world of discrete knots displays a surprising marriage of function and novelty. By leveraging the power of reverse turns, engineers and designers skillfully design solutions that protect against unforeseen vulnerabilities, committed to accuracy and capability relying on an ever-changing technological landscape.

The Truth About Oil Drain Plugs

Delving into the realm of threaded fasteners and their reverse counterparts, it’s time to shed light on a common curiosity: the nature of oil drain plug threading. The unequivocal answer is that contrary to theory, oil filters do not have rotating lines. Most of these essential features, required to facilitate oil changes in automobiles, follow the conventional traditions of automobiles.

Essentially, they feature a right-hand grip, where a clockwise rotation tightens the plug very tightly, while a clockwise rotation releases it These fixed wires ensure maintenance user-friendly system, reducing confusion and error during oil change operations. Rest assured, therefore, that when faced with the task of meeting the oil needs of your vehicle, you can rely on the convenient and widely accepted threading of the oil inlet.

Why Conventional Threading for Oil Drain Plugs?

The desirability of conventional formulations in oil drain plugs depends largely on its practical and easy-to-use characteristics. This method helps with the ease of doing regular oil changes, a task that mechanics and car owners alike want to make simple. Plug performance is optimized by adhering to standard threading procedures, allowing the use of commonly available tools such as socket wrenches without the effort of tightening and loosening

This consistent threading process not only simplifies the maintenance process but also ensures that the channel remains accessible to a wide variety of individuals, regardless of their technical skills. Ultimately, conventional solvents reflect a deliberate choice to prioritize practicality, simplify oil changes and contribute to the overall efficiency and convenience of car maintenance.

Debunking the Myth: How Did the Confusion Arise?

The persistent misconceptions about the design of most oil refinery reversals can be attributed to a combination of factors. While conventional cables are excellent, the occasional encounter with aftermarket products or specific vehicles using external cable oil pumps has caused confusion and although although such cases are rare, they play a role in perpetuating misunderstandings.

Additionally, the concept of a thread switch for oil filters has gained traction to increase safety against off-targets. This belief stems from the idea that chemical reversals act as a defense mechanism. However, manufacturers have prioritized safety through innovative engineering approaches and designs, bypassing the need for rotational processes. Clarifying this misconception and shedding light on the rarity of rear suspension wiring could give car owners and enthusiasts a more accurate understanding of wiring about the oil penetration.

When Reverse Threads Come into Play

The field of oil extraction plugs in the automotive industry is characterized mainly by conventional chemicals; However, the cars are not homogeneous and boast variety and complexity. While external fiber fasteners are not ideal for oil-filling applications, their availability provides advantages for multi-faceted industries.

Reverse threads play a specific role in specific automotive parts and systems. Notably, there is a positive use of reverse cables in the wheel mounts on some vehicles. Unlike the traditional threaded method, where after being tightened in a clockwise direction, lug poles with the horizontal threads traditionally break. Located on one side of the vehicle, these unique lug nuts go against expectations by resisting the extreme forces generated during driving

This unconventional choice is based on safety considerations. Reverse threading acts as protection against unintended ghosts caused by rotational forces generated by wheels Therefore the automotive industry’s adoption of the use of reverse threads in selected applications confirms its commitment to innovative solutions emphasizing applications aimed at enhancing safety and performance under various driving conditions.

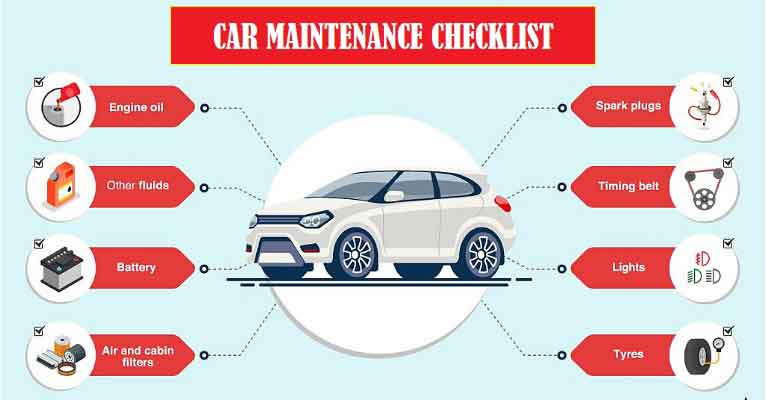

The Importance of Proper Maintenance

While the concept of a reverse threaded oil drain plug doesn’t apply to most vehicles, regular oil changes highlight the critical importance of proper maintenance and remain a cornerstone to a vehicle some engine has been running smoothly and efficiently. Neglecting this basic maintenance action can leave the vehicles exposed to a variety of potential problems, ranging from reduced engine power to permanently poor performance.

Following the manufacturer’s rules for proper torque is important to secure the oil drain plug during oil changes Over-tightening can damage threads or damage the oil pan, while not tightening properly, it can cause leaks Therefore, prioritize regular oil changes and meticulous related tasks prove to be an important way to preserve the vehicle’s peak performance and overall longevity.

Dispelling Misconceptions and Navigating Wire Fasteners

The field of wire fasteners is complex and diverse, encompassing a wide range of applications in which wire rotations play a specific role. However, it’s important to clear up the common misconception that oil drain plugs are reverse thread. Most oil pans in regular maintenance vehicles follow the standard threading rules – right-hand threads are used for tightening and left threads use to stop.

For us car owners and enthusiasts, understanding the components threaded under the hood increases our ability to confidently perform maintenance tasks It is important to consume accurate information and action of the law to enable us to maintain our vehicles despite the unconventional. So, at your next oil change, take comfort in knowing that the oil filter faithfully follows the tried and tested method of using traditional lines, demonstrating the importance of you rely on best practices in the complex world of wireless.