Laser Iridium vs. Iridium: Unraveling the Mystery Behind Spark Plugs

Spark plugs can be confusing due to the different types, such as laser iridium and iridium spark plugs. These two options greatly contribute to outstanding performance and longevity. However, it is important to understand the factors that make them different.

To shed light on the topic, let’s examine the interesting spark plugs and break down the differences between lasers and iridium.

Both Laser Iridium and Iridium spark plugs are known for their outstanding performance. It is designed to provide exceptional performance and stability. However, there are some characteristics that set them apart. By delving deeper into the subject, we can gain a broader understanding of the unique characteristics and benefits of each approach.

So, let’s start exploring the fascinating world of spark plugs, where we’ll unravel the mysteries of laser iridium and iridium spark plugs in comparison.

Understanding Spark Plugs: The Basics

To really understand the difference between laser iridium and iridium spark plugs, let’s first lay down a solid foundation. Spark plugs play an important role in the performance of an internal combustion engine. Their main function is to provide the necessary spark that burns the air-fuel mixture and initiates the combustion. This type of ignition is important because it allows the engine to start and run smoothly.

Now, let’s explore the differences between laser iridium and iridium spark plugs. These two types of spark plugs differ in design and construction, which affects their performance.

Advanced laser technology is used when making laser iridium spark plugs. This results in a central electrode with a fine edge, which makes the flame more even and intense. But conventional iridium spark plugs have a conventional iridium center electrode.

While both types work well, laser iridium spark plugs generally provide better ignition and better engine performance due to their improved spark characteristics

By delving into the basics and learning the differences between laser iridium and iridium spark plugs, we can gain a deeper understanding of their importance and impact on the overall performance of an internal combustion engine.

The Power of Iridium

Recently, the use of iridium spark plugs is increasing, mainly due to their incredible endurance and outstanding performance, these spark plugs are very popular among users.

The reason for their reliability is the precious metal iridium which is known for its exceptional corrosion resistance and high impact The addition of iridium to these spark plugs ensures longevity.

One of the key features of Iridium spark plugs is the small Iridium-plated electrode in the center. This electrode is crucial for a strong and consistent flame, which facilitates good combustion.

As a result, these spark plugs offer many benefits such as better fuel economy, smoother acceleration, and reduced emissions Iridium spark plugs provide drivers with improved mileage, driving an inexpensive, and positive impact on the environment by reducing carbon emissions they can.

The Advantages of Laser Iridium

Laser iridium spark plugs offer an advanced version of the benefits offered by traditional iridium plugs. What sets them apart is the style.

Laser welding technology carefully fuses the iridium tip with the spark plug body, strengthening the bond between the two materials. This process greatly increases the spark plug’s durability and ability to withstand damage.

The main advantages of laser iridium can be achieved as below:

- High Accuracy: Laser Iridium provides exceptional accuracy in terms of cutting, drilling, or marking due to the focused concentrated nature of the laser beam

- Non-contact processing: Laser iridium works in a non-contact manner so that no physical contact is required with the material being processed thus reducing damage or contamination.

- Versatility: Laser iridium can be used in a wide range of materials such as metals, plastics, ceramics, and even biological tissues, making it a versatile tool for a variety of industries

- Minimal thermally affected area: The laser beam of an iridium laser is larger and causes less heat dissipation in the surrounding area This results in a smaller thermally affected area, reducing material deformation or damage.

- High speed and efficiency: Laser iridium systems can operate at high speeds, allowing for faster and more efficient processing. This makes it suitable for multi-product environments.

- High-precision marking and engraving: Laser iridium can create high-precision and high-precision markings, engravings, or surface treatments on synthetic, marking, or identifying surfaces.

- Non-contact measurement: Laser iridium can be used in non-contact measurement applications, such as telemetry, thickness measurement, or surface profiling, for accurate and reliable results

- Clean and environmentally friendly: Laser iridium is clean without the use of chemicals or harmful substances. Compared to other methods, such as chemical labeling, it is environmentally friendly.

- Automation and Integration: Laser Iridium systems can be easily integrated into automated manufacturing processes, leading to increased productivity and seamless integration with other equipment

- Low cost: While the initial investment in laser iridium technology can be high, it offers long-term cost savings due to its efficiency, minimum maintenance, and reduced waste.

Laser Iridium spark plugs provide extra durability and resistance to damage due to the advanced manufacturing process. Additionally, their small electrode precision manufacturing improves combustion, engine efficiency and reduces spark plug fouling.

Maximizing Performance and Durability

Now that we clearly understand the basic differences between laser iridium and iridium spark plugs, the question arises: How do we know which one is right? The answer is to carefully consider many factors such as the specifications of your vehicle, the manufacturer’s recommendations, your driving habits and so on

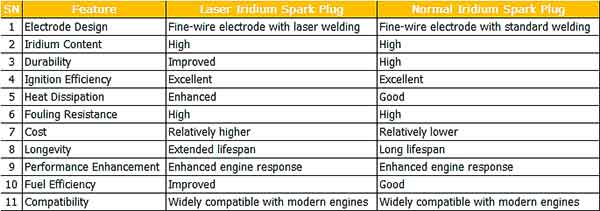

Here’s a comparison between Laser Iridium and normal Iridium spark plugs:

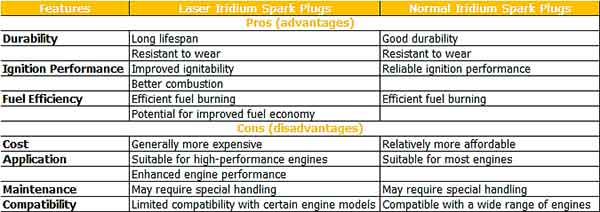

The pros and cons of laser iridium and normal iridium spark plugs:

Specific spark plugs from different manufacturers may differ in design. It is always recommended to refer to the manufacturer’s specifications for specific information on a particular spark plug model.

Laser Iridium and Iridium spark plugs work similarly due to their polished wire tips. However, there is one notable difference between their services. Laser series plugs are designed to last, typically 80 to 100 thousand miles.

On the other hand, Iridium IX® spark plugs have a rather short life, they are designed to perform well at around 40 to 50 thousand miles When considering which spark plug is best for your vehicle it is important to use this performance gap stay in mind to ensure your reliable performance long term can be maintained.

Iridium spark plugs are more than adequate for most everyday driving situations. Not only do they offer exceptional performance and longevity but they are also cost-effective compared to laser iridium plugs.

But if you happen to own a high-performance vehicle, engage in aggressive driving, or prioritize durability and unmatched performance, choosing laser iridium spark plugs may be decisive with intelligence

Ultimately, the decision between these two types of spark plugs should be based on a thoughtful assessment of your specific needs and preferences, taking into account the condition of your vehicle, driving style, and preferences that it works and lasts

Choosing the Right Spark Plugs

Obviously, Laser Iridium and Iridium spark plugs have their own advantages. Iridium plugs are known for their exceptional performance and durability, making them reliable for most vehicles.

On the other hand, laser iridium plugs get notch by notch by providing durability and efficiency, specially designed to meet the demands of harsh driving conditions

No matter what you choose; It’s important to prioritize regular maintenance and replacement of your spark plugs to keep the engine running smoothly. Be sure to check your vehicle manual for specific guidelines and recommendations.

If you are unsure or need further help, do not hesitate to seek professional advice from qualified professionals. By taking these steps, you can keep your engine running smoothly and reap the benefits of reliable spark plugs. So, wait no longer—check your brochure, contact the staff if necessary, and those sparks will fly!